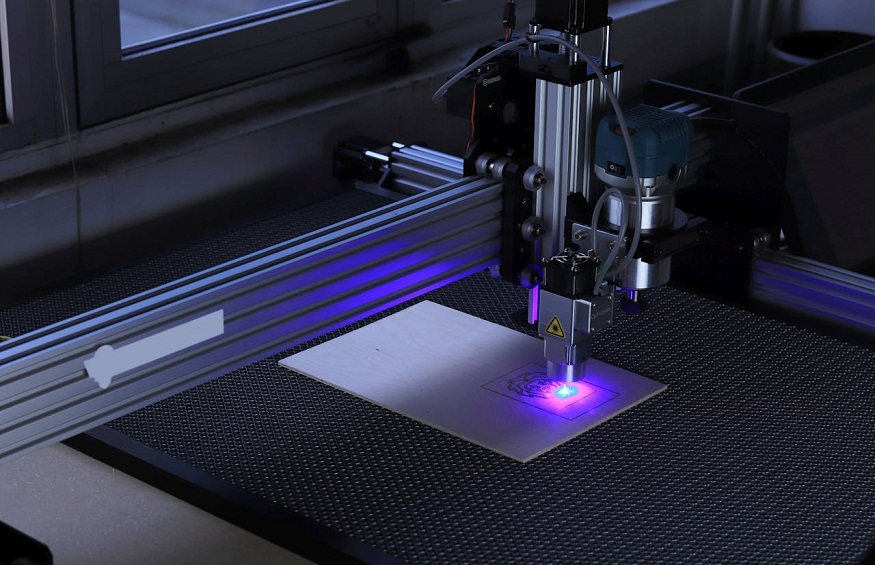

Laser cutting is a versatile and precise technology that has revolutionized the manufacturing industry. Utilizing a high-powered laser, this process can cut through various materials with incredible accuracy. From creating intricate designs to producing large quantities of products, laser cutting offers a range of benefits for businesses big and small. In this article, we will explore how laser cutting can enhance your business operations and open up opportunities for growth and innovation.

The Laser Cutting Process

Laser cutting works by directing a high-powered laser beam through the material to be cut. The intense heat generated by the laser vaporizes or melts away the material, leaving behind a clean and precise cut. This process is controlled by advanced computer software, allowing for highly detailed designs and repeatable cuts with minimal room for error.

Versatility in Materials

One of the greatest advantages of laser cutting is its ability to work with a wide range of materials. From metals like stainless steel and aluminum to non-metal materials such as wood, plastics, fabrics, and even paper, laser cutting can handle them all. This versatility allows businesses to diversify their product offerings and cater to a broader customer base.

Efficiency and Precision

Compared to traditional methods like sawing or die-cutting, laser cutting is much faster and more precise. It can create intricate designs with sharp edges, smooth curves, and even 3D shapes without any additional tooling. This level of precision not only produces high-quality results but also reduces the likelihood of errors, thereby saving time and money in the production process.

Scalability for Mass Production

Another significant advantage of laser cutting is its scalability for mass production. With advanced technology and automation, laser cutting machines can produce large quantities of products in a short amount of time with consistent quality. This makes it an ideal choice for businesses that require high-volume production, such as those in the automotive or aerospace industries.

Customization and Personalization

In addition to mass production, laser cutting also offers the ability to customize and personalize products. With computer-controlled software, businesses can easily make changes to designs and produce unique items tailored to their customers’ needs. This level of customization not only adds value to the product but also enhances customer satisfaction and loyalty.

Innovation and Flexibility

Laser cutting has opened up endless possibilities for innovation and flexibility in product design and development. With its precise and versatile cutting capabilities, businesses can create unique and complex designs that were not possible before. This allows for constant evolution and adaptation in the market, giving businesses a competitive edge.

Laser Cutting Advantages

Laser cutting advantages include: high precision, no material contamination, high speed, unlimited 2D complexity, a wide variety of materials, and a wide variety of applications and industries.

High Precision

As mentioned, laser cutting is incredibly precise, with tolerances as small as 0.1mm. This level of accuracy allows for intricate and detailed designs that would be impossible to achieve with traditional cutting methods.

No Material Contamination

Since laser cutting does not involve physical contact with the material, there is no risk of contamination from tooling or mechanical parts. This makes it an ideal choice for industries that require strict cleanliness standards, such as food packaging or medical equipment.

High Speed

Laser cutting is a high-speed process, capable of producing multiple cuts in rapid succession without compromising on precision. This makes it an efficient and cost-effective option for businesses looking to increase their production capacity.

Unlimited 2D Complexity

Unlike other cutting methods that are limited to straight lines or simple shapes, laser cutting allows for unlimited 2D complexity. This means businesses can create intricate designs and patterns without any restrictions.

Wide Variety of Materials

As previously mentioned, laser cutting can work with a wide range of materials. This makes it a versatile and cost-effective solution for businesses that work with different materials in their operations.

Wide Variety of Applications and Industries

Laser cutting has applications in various industries such as automotive, aerospace, electronics, fashion, and more. It is not limited to a specific type of product or material, making it a valuable tool for businesses across different sectors.

Disadvantages of Laser Cutting

While laser cutting offers numerous advantages, there are also some limitations to consider before incorporating it into your business operations.

Material Thickness Limitations

Laser cutting is best suited for materials up to a certain thickness. Beyond that, it may not be as precise or cost-effective compared to other cutting methods. It is essential to consider the material requirements of your products before deciding on laser cutting.

High Initial Investment

The cost of purchasing and maintaining a laser cutting machine can be high, making it less accessible for small businesses or startups. However, for businesses that require precision and efficiency in their production processes, the initial investment may be worth it in the long run.

Harmful Gasses and Fumes

Laser cutting produces harmful gasses and fumes, which can be dangerous if not properly ventilated. Businesses must ensure proper safety measures are in place to protect employees and the environment.

High Energy Consumption

The use of high-powered lasers requires a significant amount of energy, which can result in higher production costs. Businesses must consider the energy consumption and costs in their budget when using laser cutting.

Applications of Laser Cutting

The versatility and precision of laser cutting make it suitable for a variety of applications. In the manufacturing industry, laser cutting is commonly used for prototyping, custom parts production, and large-scale fabrication. Its ability to cut through different materials also makes it popular in industries such as signage, jewelry making, and medical device manufacturing.

In addition to traditional applications, laser cutting has also opened up new opportunities for businesses to innovate and diversify their offerings. For example, the rise of laser cutting in the fashion industry has allowed designers to create intricate and unique designs on fabrics that were previously impossible to achieve.

Incorporating Laser Cutting into Your Business

Integrating laser cutting into your business operations can bring numerous benefits. However, it is essential to consider various factors before investing in this technology. These may include the types of materials you work with, the level of precision required, and the volume of production. West Australian Steel Sales is a major service provider of laser cutting in the west coast of Australia. You can inquire with them about laser cutting for all your precision cutting needs.

Fortunately, there are various options available for businesses looking to incorporate laser cutting. Many companies offer laser cutting services, allowing businesses to outsource their cutting needs without having to invest in expensive equipment themselves. Alternatively, businesses can also consider purchasing their own laser cutting machines, which can provide more control and flexibility over the production process.

Alternatives to Laser Cutting

If laser cutting is not suitable for your business, there are alternatives available that may better fit your needs. These include water jet cutting, plasma cutting, and mechanical cutting methods such as milling or sawing.

Conclusion

In conclusion, laser cutting offers a wide range of advantages for businesses looking to enhance their operations and expand their capabilities. Its versatility, precision, and efficiency make it a valuable tool in various industries and applications. By incorporating laser cutting into your business, you can improve product quality, increase production speed, and open up opportunities for innovation and growth. Consider exploring the possibilities of laser cutting for your business and see how it can help take your operations to the next level.