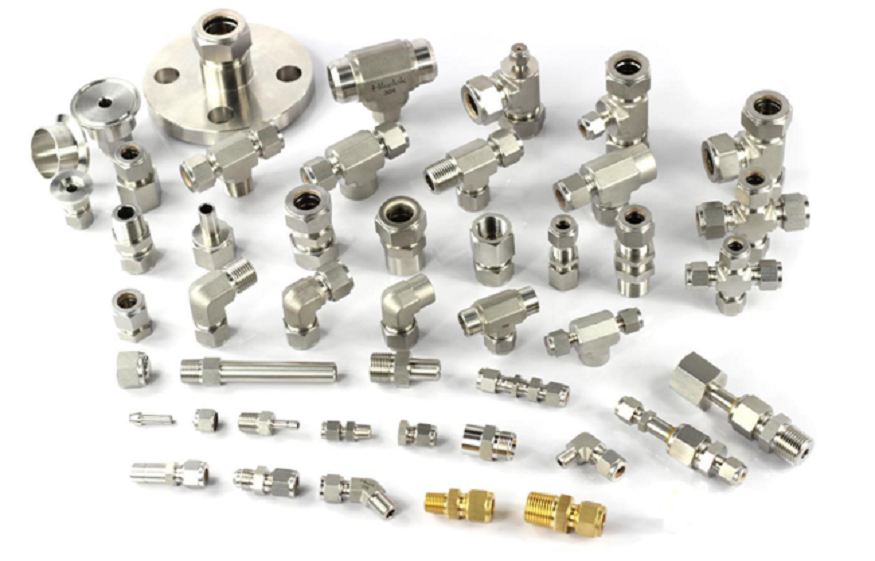

If you want to connect metals or hard plastic tubes, stainless steel compression

fittings stand to be the most popular and versatile method. Notably, it has got some unique features like handling extreme temperatures and pressure and is compatible with aggressive fluids. It is widely used by different types of industries like gas lines in refineries, power plants, etc. Moreover, it is also seen in your homes under your sink. All you need to know about the compression fittings are enumerated below.

Installation

All manufacturers have different stainless steel compression fittings instructions depending on the type of industry it is. Follow the instructions well before putting things together. But, there are a few things that stand common to all compression fittings while they are installed.

Shape Is Everything

When you buy something, the first factor is its reliability. The same goes for compression seals. The ferrule’s shape, the body fittings, and the mating angle should be ensured well before you use it. Some qualities to mention are:

- With the nuts tightened, they should be tapered to allow proper compression.

- Tubing and axial alignment

- The relative angle determines the amount of linear motion. It will turn into radial compression.

One Piece vs. Two Piece Ferrules

The single ferrule is the most basic compression fittings. Note that single ferrule increases work efficiency with soft material fabrication designs. When working with hard materials, the torque shifts from its position to the single ferrule from the nut fittings as it is tight. While with stainless steels, there is no flow of torque because of the freely rotating rear ferrule that can help decouple the nut from the front ferrule.

Metal Tubing

The production process makes all the difference in the way it functions. Smooth tubing with no hardness or roughness is one type, but it cannot ensure to save you from leakages. Note: the metal-to-metal seal is cannot adjust much as an elastomeric seal can because it can be deformed.

Applications

Stainless steel compression fittings are heavily used in:

- Chemical industries

- Pressure vessels

- The oil and gas refinery also has a high demand.

- Other industries include food, chemical, pharmaceutical, beverage, and other industries. Industrial structural parts and mechanical transportation pipelines such as medical treatment, petroleum, light industry, chemical industry, food, and mechanical instrumentation are users of stainless steel compression fittings.

Material Specification of Double Compression Fittings

- Types- Tube to Male and Female, Tube to Union, Instrument Pipe Fitting, and, Accessories

- Ends- Welding, Threaded, JIC

- Standard- There are several types like the ASME SA-479, 304-SS, DIN 4401, ASTM A276 Type 304, BS 970 304S11

- Sizes- 1/8’’- 2’’ and 3mm – 50mm

- Pressure Rating- It includes 3000 Psi, 6000 Psi, 1000 Psi, 10000 Psi

- Specification- Products manufactured from Round Bar- ASTM A182, and products made out of Hex – ASTM A276

Conclusion

So many industries’ applications run with the help of these fittings. So, it is understood that these stainless steel compression fittings are undoubtedly the power hub of any industry. Thanks to those who have invented this mechanism which has helped the market grow much higher than ever before.