8,091 Views

Many companies save their products on pallets in the warehouse, and there is some warehouse pallet racking melbourne that the storage methods that recognize the warehouse staff to store pallets efficiently. Standard pallet storage systems include Block stacking, Double deep rack, drive-in rack. Pallet flow rack, Single-deep pallet rack, stacking frames and Push back rack.

7 Ways To Store Standard Pallet

- Block Stacking. It refers to system loads piled on top of each other and collected on the warehouse floor in ways or blocks. The way to a garage shelving ideas, the pallets are accumulated to a particular height based on some principles such as pallet position, the weight of the load, height allowance and the capacity of the warehouse forklifts. The pallets are recovered from the block in a last in, first out (LIFO) manner. This does not provide for transferring stock based on data security or first in (FIFO). Removal of stock can make honeycombing to transpire where blank spaces occur that cannot be charged until the whole way is empty. This system is common to implement as it requires no racking and can be completed in any warehouse with open floor space.

- Stacking Frames. Pallet stacking frames are constructed up from floors and posts that can be constructed and passed if necessary. The stacking frame enables pallets to be stored sparse high and is especially useful when the pallets to be deposited are not stackable. Many companies will practice stacking frames in the warehouse when they require temporary racking during active period periods. With stacking frames, the number of honeycombing lives related to block stocking.

- Single-Deep Pallet Rack. The introduction of this grant to each pallet stored in the rack. This grows around the honeycombing effects of stacking frames and block stacking. When a pallet is unloaded, space is instantly available for a new pallet to be placed in that space. This type of racking can be configured in any number of systems with different heights. Most warehouses today have this type of racking in control. The principal disadvantage is that the racks need important floor space for suitable aisles.

- Double-Deep Pallet Rack. It is a variant on the single-deep rack that incorporates two single racks that are placed together. This reduces the number of aisles required but this type of racking is sensitive to honeycombing, so may not be as efficient as single-deep racking. Also, a double reach forklift is required to place and remove pallets from the racking.

- Drive-In racks produce five- to 10-pallet load spaces related to the double-deep racking. The drive-in lanes grant path for the forklift to place and transfer stock. However, the forklift has a defined space to move, and this improves the time needed to place and push pallets. The drive-in rack is related to block stacking as the LIFO principle is used for pallet retrieval.

- Pallet Flow Rack. It works whereby the load is transferred from one end of the rack on a conveyor that enables the pallets to be raised in a FIFO manner. Once a pallet is pushed the next pallet moves into the area of the pallet that was removed. This racking solution is proper for warehouses that have large throughput but is an invaluable option. But is an expensive choice.

- Push Back Rack is a LIFO suspension where the load is set into storage using a rail-guided carrier. When a load is stored into storage, the load forces the other loads back into the storage space.

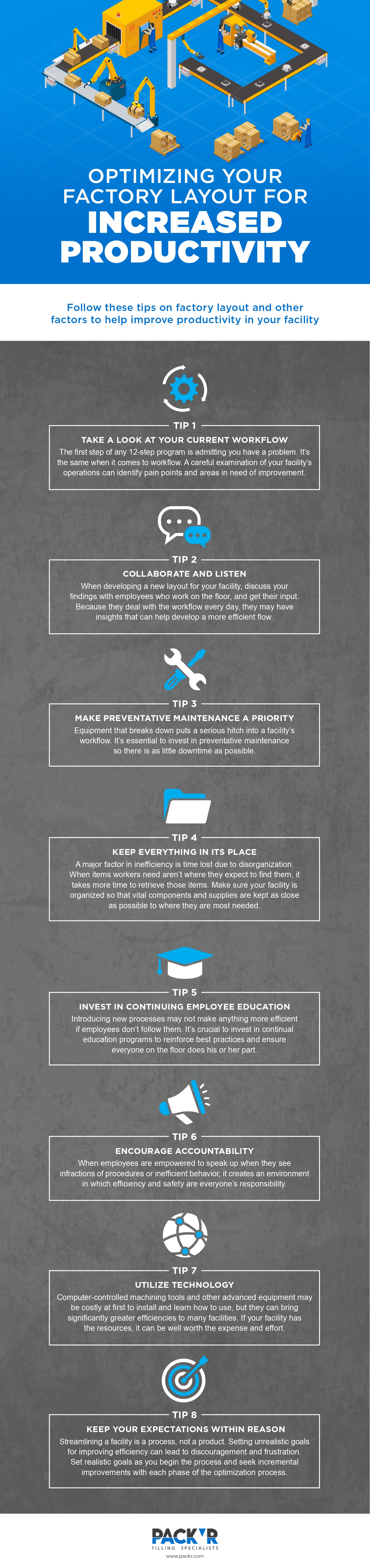

Knowing how to store your pallet racking is only one small part of facility management. For more tips on running your faciity to its highest potential efficacy, check out the infographic below!

Infographic provided by PACK’R, a liquid filling machine company